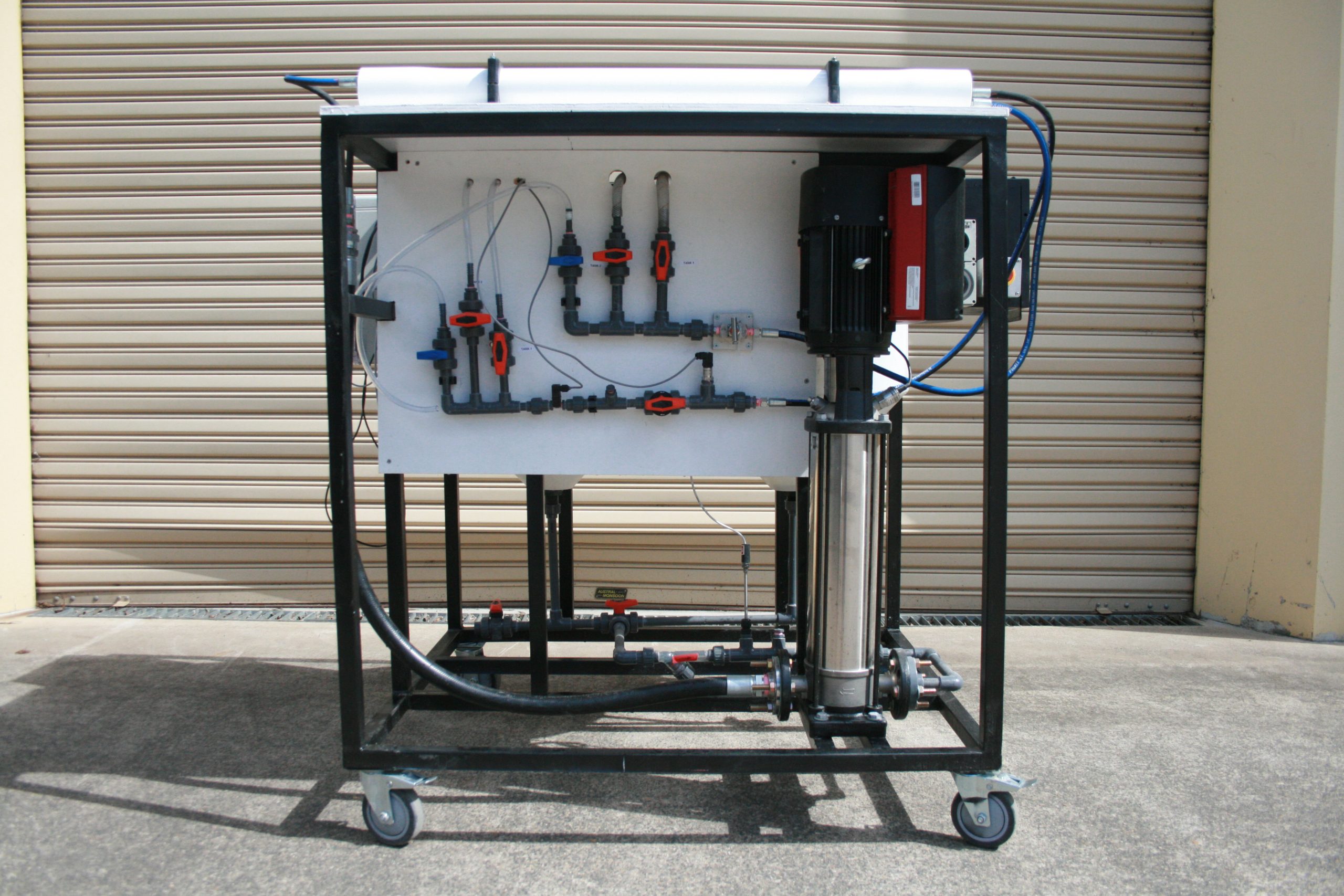

Membrane works are proud to showcase our new pilot Reverse Osmosis and Nanofiltration membrane rig. This rig is a new tool for running pilot testing of the most difficult to treat waters, in those moments where we see the predictive models are no longer effective. With a flexible design we can either run a range of pilot treatment studies either at our facilities or onsite at your water treatment plant.

The rig includes:

- 2.5″ Membrane module with the option of fitting 4″ and 8″ modules if required

- Able to use all major supplier membranes including; Dow, Hydranautics, LG, Torray

- Feed and permeate flow meters for recovery calculation

- Feed and permeate pressure transducers for trans-membrane pressure measurement

- Feed and permeate conductivity probes for salt flux calculation

- Operational pressure up to 20 bar

- 2x100L feed tanks for a wide range of operations

- Sampling for a wide range of off-line analysis

We are now better able to conduct lab and field pilot studies including:

- Standardized flux and salt-rejection of full-sized modules to determine membrane life

- Full size membrane pilot runs for difficult to treat waters

- Membrane failure studies – to evaluate achievable recovery and what failure mechanisms will occur as you stress your system to the max

- Scale inhibitor effectiveness testing

- Membrane cleaning studies

Membrane life-assessment: Flux and Salt Passage

One of the most common questions we get during an autopsy is: How long will my membrane last? For us to answer this we need to look at the membranes performance under a standardized set of conditions (standard water composition, pressure and flow rates) that are given by the manufacturer. When we run the membrane under these conditions we can compare to as-new performance and expected aging profiles to assess how much life the membrane still has.

Flux (the rate water passes through the membrane measured as Litres per m2 per hour or LMH) is important here as it shows how well the membrane is still producing clean water. It can be permanently degraded by scale or aging of the membrane surface and some types of chemical damage.

Salt-passage (measured in %) is a measure of the amount of salt that passes through the membrane. This is an indication of the integrity of the sensitive active layer on the membrane surface and how it has been degraded by oxidation, abrasion, physical damage or other chemical damage.

Pilot Water Testing

Pilot testing is most often used to determine the treatability of more difficult waters. It is often found that for industrial or mining water, the composition is so different to standard water that the models will struggle to adequately predict the treatment requirements. However, we also conduct pilot testing to help an existing plant understand what their maximum possible recovery is and how to get there. Likewise, we can also screen new antiscalant chemicals to help you make sure that there won’t be any problems before you implement it on site.

Membrane Cleaning Studies

Membrane cleaning studies are most commonly conducted on either flat-sheets of RO membrane or UF filaments that are potted into micro-membrane rigs. However, this is a destructive method and while the autopsy gives additional information, at times its desirable to test clean a full membrane. This rig allows us to do this effectively for those clients who prefer a whole element test.

Contact us today to find out more about our range of on-site and off-site piloting options.